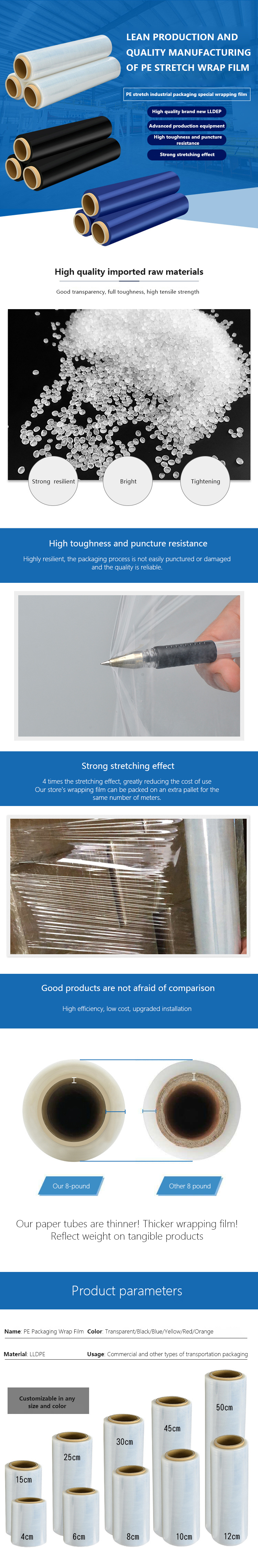

Tray wrapped wrapping film The use cost is greatly reduced, the same number of meters, our winding film can be more than one tray

Transportation and handling of wrapping film Good quality, strong toughness, will not break when used, packaging products reliable

Payment terms:We accept T/T,LC,DP and OA30,etc.

Choosing a stretch film of appropriate thickness requires comprehensive consideration of factors such as the characteristics of the packaged items, packaging methods and requirements, storage and transportation environment, etc.:

Consider the characteristics of the packaged items

Weight

Tray wrapped wrapping film Heavy goods: such as large machinery, building materials, etc., which usually weigh hundreds of kilograms or even tons, require a stretch film with a thickness of 18 microns to 30 microns, such as 23 microns and 28 microns, which can withstand the weight of the goods with high tensile strength and tear resistance to prevent breakage during transportation.

Tray wrapped wrapping film Light goods: small electronic products, food, etc., generally choose a stretch film of 12 microns to 18 microns, such as 15 microns, which is enough to fix and protect the goods and reduce costs.

Shape

Tray wrapped wrapping film Regular shape: For regular-shaped items such as cartons, cubes or cylinders, the force is relatively uniform, and a slightly thinner stretch film can be selected, such as 15 microns to 18 microns to ensure the packaging effect.

Transportation and handling of wrapping film Irregular shape: For items with complex shapes, sharp corners or protruding parts, such as furniture, pipes, etc., in order to avoid the wrapping film being punctured, products with a thickness of 18 microns to 25 microns should be selected to enhance the puncture resistance.

Surface characteristics

Transportation and handling of wrapping film Smooth surface: For items with smooth surfaces, such as glass products, metal products, etc., the friction requirements of the wrapping film are low. You can use a wrapping film with a thickness of 12 microns to 15 microns, relying on its good transparency and flexibility for packaging.

Rough surface: If the surface of the item is rough, such as stone, wood, etc., it is easy to wear the wrapping film. You need to choose a wrapping film with a thickness of 18 microns to 23 microns to improve wear resistance.

Consider packaging methods and requirements

Transportation and handling of wrapping film Packing methods

Transportation and handling of wrapping film Manual packaging: When manually operating, in order to facilitate stretching and winding, you can choose a wrapping film with a thickness of 12 microns to 18 microns. This type of wrapping film has good softness and is easy to operate.

Mechanical packaging: Use wrapping machines and other equipment for packaging. You can choose a wrapping film with a thickness of 18 microns to 30 microns. The machine can provide sufficient tension. Thicker wrapping films can better play their advantages of high strength and have higher packaging efficiency.

Packaging requirements

High tightness requirements: For precision instruments, electronic products, etc., in order to prevent the intrusion of dust, moisture, etc., they need to be tightly packed. You can choose a wrapping film of 18 microns to 25 microns, which can better achieve a tight fit.

High display requirements: For situations where the appearance of the product needs to be highlighted, such as goods on supermarket shelves, you can choose a thin wrapping film of 12 microns to 15 microns. Its high transparency can fully display the product.