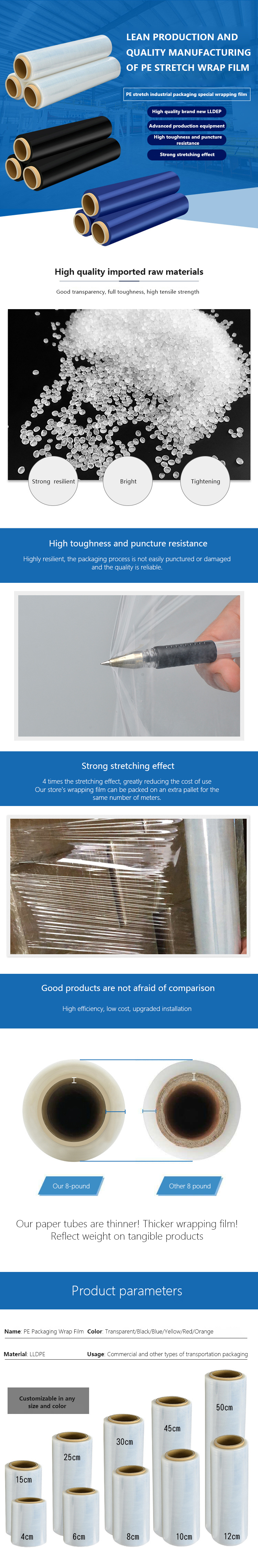

Large roll PE stretch film Wrap film wear resistance, service life longer

Moving cardboard box plastic film Paper tube chamfer winding does not hurt hands

Self adhesive PE packaging stretch film New materials customized, flexible and flexible

Payment terms:We accept T/T,LC,DP and OA30,etc.

Large roll PE stretch film In addition to the material, the stretch ratio of the stretch film is also affected by the production process, additives, environmental factors, equipment and operation, as follows:

Production process

Large roll PE stretch film Blow molding process parameters: Parameters such as temperature, blow ratio and traction speed in the blow molding process have a significant impact on the stretch ratio of the stretch film. If the temperature is too high, the molecular chain movement of the film will intensify, which will reduce the tensile strength of the stretch film. The stretch ratio may increase but the stability will deteriorate; if the blow ratio is large, the film will be stretched to a large extent in the transverse direction, and the molecular chain orientation will be high, which will increase the transverse stretch ratio; if the traction speed is fast, the longitudinal stretch ratio will increase accordingly.

Large roll PE stretch film Casting process parameters: The cooling rate and extrusion speed in the casting process will also affect the tensile properties of the stretch film. Rapid cooling will prevent the molecular chain from fully crystallizing and oriented, which may reduce the stretch ratio of the stretch film; while appropriately increasing the extrusion speed can make the molecular chain have better orientation in the flow direction, which helps to increase the longitudinal stretch ratio.

Additives

Self adhesive PE packaging stretch film Plasticizers: Adding plasticizers can increase the flexibility and plasticity of the stretch film, reduce its hardness and brittleness, and usually increase the stretch ratio of the stretch film. However, if too much plasticizer is added, the strength of the stretch film will decrease, affecting its performance.

Self adhesive PE packaging stretch film Antioxidants and light stabilizers: Additives such as antioxidants and light stabilizers are mainly used to improve the aging resistance of the stretch film, but some antioxidants and light stabilizers may interact with the resin matrix, affecting the movement and orientation of the molecular chain to a certain extent, thereby indirectly affecting the stretch ratio.

Environmental factors

Moving cardboard box plastic film Temperature: Temperature has a greater impact on the stretch ratio of the stretch film. Generally speaking, as the temperature rises, the thermal motion of the molecular chain of the stretch film intensifies, the intermolecular force weakens, the stretch film becomes softer, and the stretch ratio increases; as the temperature decreases, the stretch film becomes harder and brittle, and the stretch ratio decreases.

Moving cardboard box plastic film Large roll PE stretch film Humidity: For some stretch film materials with strong hygroscopicity, changes in humidity will affect their internal molecular structure and performance. In a high humidity environment, moisture may penetrate into the stretch film, play a plasticizing role, and increase the stretch ratio of the stretch film; in a dry environment, the stretch film may become brittle and hard due to water loss, and the stretch ratio decreases.