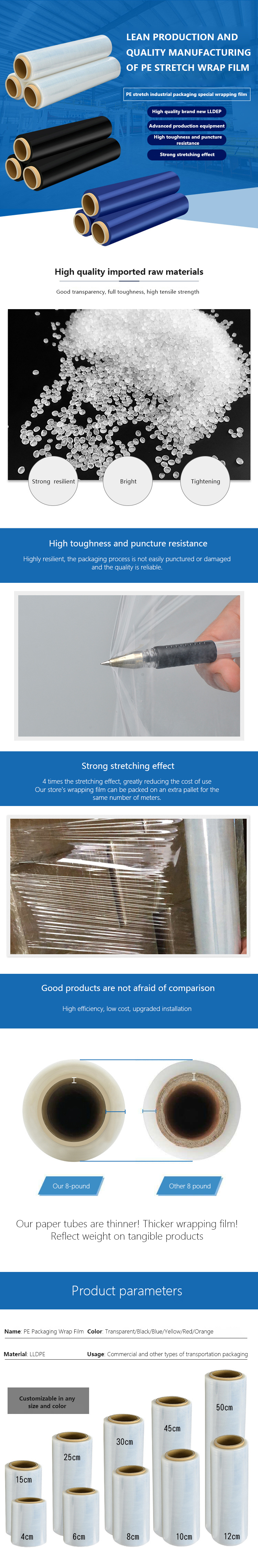

Heavy duty plastic shrink film Good puncture resistance toughness enhancement is not easy to Pierce

Plastic stretch film Preferably made of new materials, full toughness, high light transmittance, quality assurance

PE packaging wrapping film The imported viscosifying masterbatch makes the winding film have high self-viscosity, and the tight winding is not easy to fall off.

Payment terms:We accept T/T,LC,DP and OA30,etc.

When buying a Heavy duty plastic shrink film Plastic stretch film PE packaging wrapping film, there are many factors to consider, such as material, specifications, and performance. The following are detailed purchase instructions:

Pay attention to product parameters

PE packaging wrapping film Material: Common stretch film materials include PE (polyethylene), PVC (polyvinyl chloride), POF (polyolefin), etc. PE Heavy duty plastic shrink film has good flexibility, transparency, and puncture resistance, and is non-toxic and odorless, and is widely used; PVC stretch film has high tensile strength, but may contain harmful substances, and is limited in some areas with high environmental protection requirements; POF Heavy duty plastic shrink film has high transparency and good shrinkage, and is suitable for packaging with high appearance requirements.

PE packaging wrapping film Thickness: The thickness of the stretch film is generally between 15μm-50μm. The greater the thickness, the higher the strength and durability of the Heavy duty plastic shrink film, but the cost also increases accordingly. For general light and small item packaging, you can choose a 15μm-25μm thick stretch film; for heavier or irregularly shaped items that are easy to puncture the packaging, you need to choose a 30μm-50μm thick stretch film.

Plastic stretch film Width and length:Plastic stretch film Choose the appropriate width and length according to the size of the actual packaging items and packaging requirements. Common widths are 500mm, 450mm, 300mm, etc., and lengths are 50m, 100m, 200m, etc. If you are packaging large goods, you can choose a wrapping film with a larger width; for small items, a wrapping film with a narrow width is easier to operate.

Plastic stretch film Tensile properties: including stretch ratio and tensile strength. The higher the stretch ratio, the more area can be covered with less material during packaging, reducing costs; the tensile strength determines whether the wrapping film is easy to break during the stretching process. High-quality wrapping film should have a high tensile strength and an appropriate stretch ratio. Generally, the stretch ratio is between 200%-500%.

Heavy duty plastic shrink film Viscosity: The viscosity of the wrapping film is divided into self-adhesive and adhesive-coated. Self-adhesive wrapping film relies on the characteristics of its own material to produce viscosity, which is relatively weak but environmentally friendly; adhesive-coated adhesive wrapping film increases viscosity by coating glue on the surface, which is strong but may have odor or environmental problems. Choose the appropriate stickiness of the stretch film according to the packaging needs. For example, for items with high stickiness requirements, you can choose adhesive stretch film. However, in areas with strict environmental requirements such as food packaging, self-adhesive stretch film should be given priority.