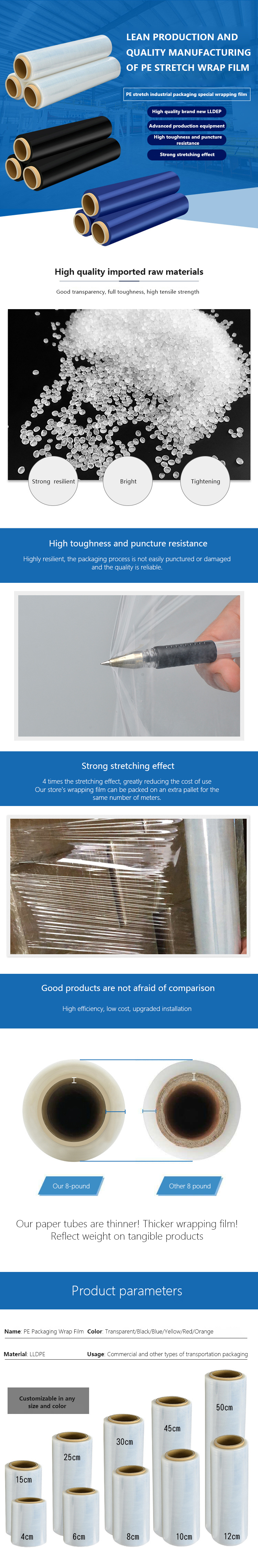

PE plastic film The paper tube is smooth and smooth

Industrial transport film Bright color, bright luster

Large plastic stretch film Strong and stretchy, not easy to puncture

Payment terms:We accept T/T,LC,DP and OA30,etc.

The influence of the stretch ratio of the wrapping film on the packaging efficiency is mainly reflected in the following aspects:

Low stretch ratio

PE plastic film Wrapping speed: Low stretch ratio means that the wrapping film does not need to apply too much tension to stretch during the wrapping process, and the operation is relatively easy. Workers can wrap relatively quickly when manually wrapping. In mechanical wrapping, the equipment does not need to adjust the tension parameters too much, and can wrap at a relatively stable speed, which can increase the wrapping speed to a certain extent.

Operational convenience: Due to the low stretch ratio, the wrapping film is relatively loose, and it is not easy to break during the wrapping process. Workers do not need to frequently deal with broken wrapping films during operation, nor do they need to frequently replace wrapping film rolls, thereby reducing the time wasted in dealing with these problems and improving the continuity and efficiency of packaging.

Cargo stacking coordination: For situations where multiple people need to collaborate to stack and wrap cargo, Large plastic stretch film with low stretch ratios will not bring too many restrictions to cargo stacking. Stacking workers can adjust the position of cargo more freely without worrying about the tightness of the Large plastic stretch film affecting the stacking operation, making the packaging process smoother and improving the overall packaging efficiency.

High stretch ratio

Fastening efficiency: Stretch film with high stretch ratio can produce greater retraction force after stretching, and only needs to be wound with fewer turns to achieve a good fastening effect. Compared with low stretch ratio, which requires multiple turns to fix the goods, it can save the number of turns and time, thereby improving packaging efficiency.

PE plastic film Time-consuming stretching operation: When manually wrapping, it takes more effort and time to stretch the Large plastic stretch film to a higher ratio. Workers may need to rest more frequently to recover their strength, which will reduce the overall packaging efficiency. In mechanical wrapping, although the equipment can automatically stretch the PE plastic film, a high stretch ratio may increase the load on the equipment's stretching system, requiring more complex parameter settings and adjustments, and may even cause equipment failure, resulting in interruptions in the packaging process and affecting packaging efficiency.

PE plastic film Risk of film breakage:PE plastic film A high stretch ratio will put the PE plastic film in a highly tense state, increasing the risk of breakage. Once the stretch film breaks during the wrapping process, it is necessary to stop the machine or suspend the operation to reconnect or replace the stretch film, which will waste a lot of time and seriously affect packaging efficiency. Moreover, frequent film breaks may also lead to waste of packaging materials and increase packaging costs.