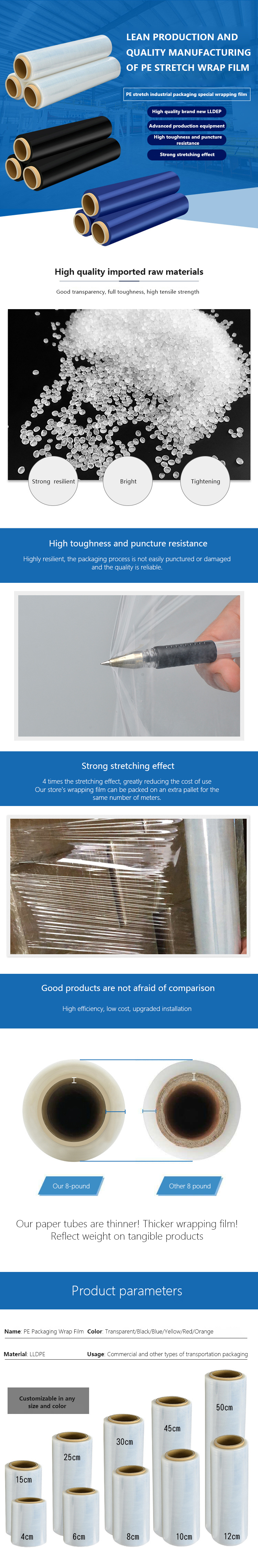

PE packaging film The use cost is greatly reduced, the same number of meters, our winding film can be more than one tray

Plastic film protective film Good quality, strong toughness, will not break when used, packaging products reliable

Commercial cling film The imported viscosifying masterbatch makes the winding film have high self-viscosity, and the tight winding is not easy to fall off.

Payment terms:We accept T/T,LC,DP and OA30,etc.

Plastic film protective film PE packaging film There are many ways to use stretch film in the field of industrial packaging. Here are some common types and operation methods:

Manual wrapping

Plastic film protective film PE packaging film Preparation: Choose a stretch film with appropriate width and thickness. Generally, a width of about 500mm and a thickness of 15-50 microns are more commonly used. At the same time, prepare auxiliary tools such as scissors and utility knives.

PE packaging film Cargo fixing:Commercial cling film Stack the goods neatly on the pallet or other carrier to ensure the stability and neatness of the goods. If the goods have irregular shapes or protruding parts, they can be properly sorted or protected first.

PE packaging film Start wrapping: Fix one end of the stretch film to the bottom edge of the pallet or goods. You can use tape to stick it or directly insert one end of the film into the gap at the bottom of the goods. Then pull the stretch film up from the bottom and wrap it around the goods at a certain angle, generally at an angle of about 45 degrees to the surface of the goods, so that the stretch film can better fit the goods and provide uniform tension.

Commercial cling film Wrapping process: Wrap the goods in a spiral shape. Each circle of the wrapping film should overlap with the previous circle to a certain extent. The overlapping part is generally 1/3 to 1/2 of the width of the wrapping film to ensure the tightness and stability of the wrapping. During the wrapping process, maintain appropriate tension so that the wrapping film can tightly wrap the goods, but also pay attention to avoid excessive tension that may cause deformation of the goods or breakage of the wrapping film.

Commercial cling film End fixation: When wrapping to the top of the goods, fix the end of the wrapping film. You can stick it with tape or cut it with scissors and then stuff the end of the film into the wrapped film layer.

Equipment and operation

PE packaging film Stretching equipment type: Different types of stretching equipment apply different stretching forces and stretching methods to the stretch film. For example, there may be differences in the stretching effects of mechanical stretching equipment and hydraulic stretching equipment.Commercial cling film The stretching force of mechanical stretching equipment is relatively stable, but the stretching speed may be limited; hydraulic stretching equipment can provide greater stretching force, and the stretching speed can be adjusted in a wider range, which can enable the stretch film to achieve a higher stretching ratio.