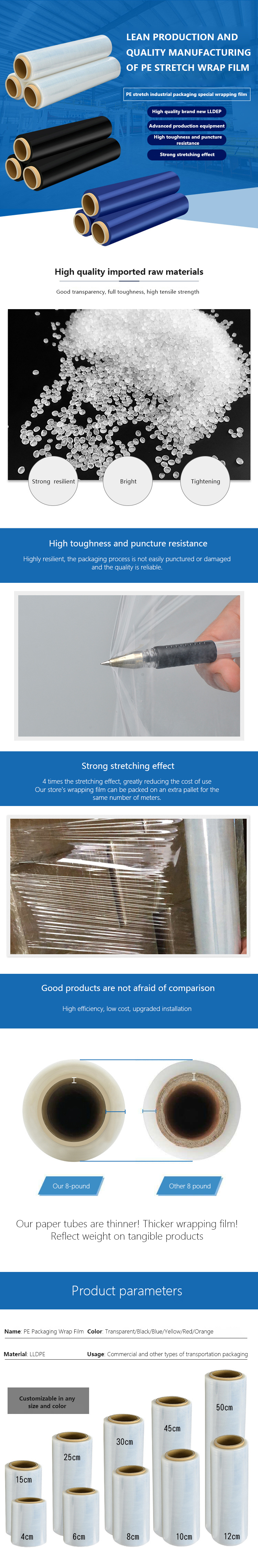

50cm wrapping film Environmental protection casting process high toughness and strong tensile

Small roll PE wrapping film The raw material is selected LLDPE material, transparent without variegations, and the packaging products are beautiful and generous.

Payment terms:We accept T/T,LC,DP and OA30,etc.

50cm wrapping film High efficiency:

High degree of automation, fast production speed, suitable for large-scale production.

Small roll PE wrapping film:

Precise temperature and velocity control ensures uniformity of film thickness and performance.

Flexibility:Small roll PE wrapping film PE large roll packaging film The thickness, width and tensile ratio of the film can be adjusted according to customer requirements. Custom machine with color film.

50cm wrapping film To select a suitable thickness of stretch film, you need to consider the characteristics of the packaged items, packaging methods and requirements, storage and transportation environment and other factors:

Considering the storage and transportation environment

Storage environment

50cm wrapping film Indoor dry environment: In indoor warehouses with relatively stable temperature and humidity, the protective performance requirements of the stretch film are relatively low. Selecting a 15-18 micron stretch film can meet basic protection needs.

50cm wrapping film Outdoor or humid environment: If the items need to be stored outdoors or in a humid environment, a stretch film with a thickness of 23-30 microns should be selected to enhance moisture-proof and anti-aging properties.

Transportation distance

50cm wrapping film Short-distance transportation: When the transportation distance is short and the number of handling times is small, a stretch film with a thickness of 15-18 microns can be used to meet short-term protection needs.

50cm wrapping film Long-distance transportation: For long-distance transportation of goods, considering that they may face more bumps, collisions and environmental changes, it is recommended to choose a stretch film with a thickness of 18-25 microns to ensure effective protection of the goods throughout the transportation process.

Reference to cost and efficiency

Small roll PE wrapping film Cost factor: On the premise of meeting the packaging requirements, choosing a stretch film of appropriate width can effectively control costs. If you choose a stretch film that is too wide, the material cost will increase; if you choose a stretch film that is too narrow, you may need to splice or wrap it multiple times, which will increase labor costs and packaging time. Therefore, it is necessary to comprehensively consider the material cost and labor cost to find a balance.

Small roll PE wrapping filmPackaging efficiency: The appropriate width of the stretch film can improve packaging efficiency. For example, for small items packaged in batches, choosing a narrower stretch film can quickly package them individually; and for large pallet cargo, choosing a sufficiently wide stretch film can reduce the number of windings and improve overall packaging efficiency.