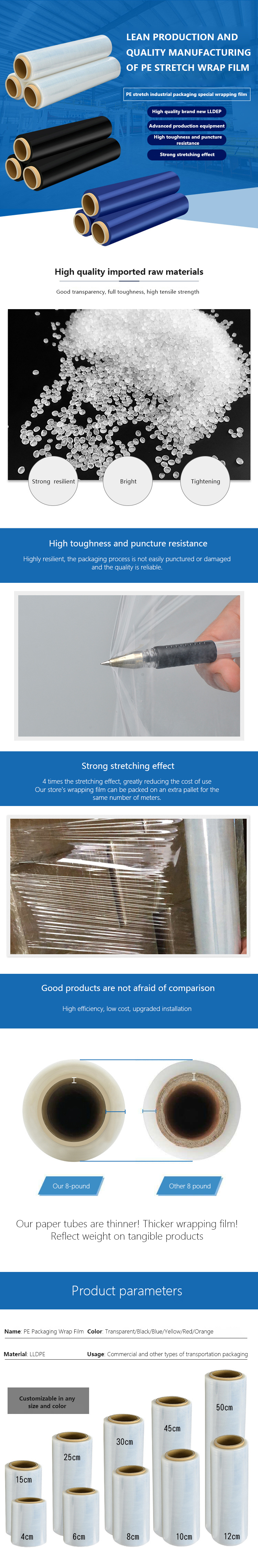

PVE packaging film Good puncture resistance toughness enhancement is not easy to Pierce

Plastic wrapped stretch film Preferably made of new materials, full toughness, high light transmittance, quality assurance

Payment terms:We accept T/T,LC,DP and OA30,etc.

The thickness of the stretch film has many effects on its performance and application:

Effect on performance

PVE packaging film Tensile strength: Generally speaking, the tensile strength of the stretch film will increase with increasing thickness. Thicker stretch films are less likely to break during stretching, can withstand greater tension, and can better adapt to different stretch packaging needs to ensure that they will not break due to excessive stretching during packaging.

PVE packaging film Toughness and puncture resistance: As the thickness increases, the toughness of the stretch film increases and the puncture resistance also improves. Thicker stretch films can better resist punctures from sharp objects, reducing the risk of punctures when packaging items with sharp edges, thereby providing more reliable protection for the packaged items.

PVE packaging film Transparency: Generally, a thinner stretch film has higher transparency, which can make the packaged items clearly visible and easy to identify and view. Thicker stretch films may reduce transparency to a certain extent, but some high-quality thick stretch films can also maintain good transparency through special processes.

PVE packaging film Self-adhesion: The self-adhesion of the stretch film mainly depends on its material and surface treatment, but the thickness will also have a certain impact. Thicker wrapping film has a larger contact area between layers during the wrapping process, and the self-adhesiveness may be more obvious, which can better maintain the shape after wrapping and prevent looseness.

Weather resistance: Increasing the thickness is conducive to improving the weather resistance of the wrapping film. In outdoor environments, thicker wrapping films can better resist the erosion of natural factors such as ultraviolet rays, wind and rain, slow down the aging speed, extend the service life, and maintain the stability of its performance.

Impact on applications

Industrial packaging

PVE packaging film Heavy goods:Plastic wrapped stretch film For heavy goods with large weight and volume, such as large mechanical equipment, metal castings, etc., thicker wrapping films are required to provide sufficient tensile strength and puncture resistance to ensure that the goods are firmly fixed and protected during transportation and storage.

PVE packaging film Light goods:Plastic wrapped stretch film Light goods such as small electronic products, parts, etc. have relatively low requirements for the tensile strength and puncture resistance of the wrapping film. Thinner wrapping films can be used, which can not only meet packaging needs, but also reduce costs and facilitate operation.

Food packaging

Plastic wrapped stretch film Short-term preservation: For foods that are stored and sold for a short period of time, such as fresh fruits and vegetables in supermarkets, thinner wrapping films are generally used, which can not only play a certain role in preservation, but also allow consumers to clearly see the appearance of the food and attract purchases.

Plastic wrapped stretch film Frozen food: Frozen food needs to withstand low temperatures and possible collisions during storage and transportation. It is usually necessary to use slightly thicker wrapping films to ensure that it still has good toughness and crack resistance in low temperature environments to prevent packaging from breaking and causing food deterioration.

Other applications

Plastic wrapped stretch film Irregular shaped items: When packaging irregular shaped items, thicker wrapping films can better fit the surface of the items, fill gaps, and achieve tight wrapping due to their good toughness; while thin wrapping films may easily break or fail to fully cover during the wrapping process.