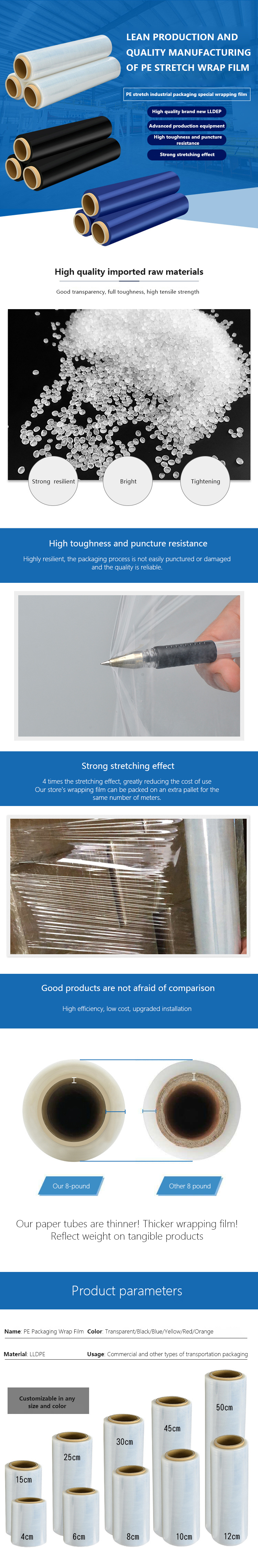

PE enclosure film Wrap film wear resistance, service life longer

Packaging and transportation stretch film Paper tube chamfer winding does not hurt hands

Large roll stretch film New materials customized, flexible and flexible

Payment terms:We accept T/T,LC,DP and OA30,etc.

Temperature changes mainly affect the stretch ratio of the stretch film by affecting its molecular motion, crystallinity, and elastic modulus:

Temperature increase

Large roll stretch film PE enclosure film Intensified molecular chain motion: Stretch film is usually made of polymer materials. When the temperature rises, the molecules gain more energy and the thermal motion becomes more intense. The interaction force between the molecular chains is weakened, and the molecular chains are more likely to slide and orient relative to each other. During the stretching process, the molecular chains can be arranged more smoothly along the stretching direction, so that the stretch film can be stretched to a greater extent and the stretch ratio is increased.

Large roll stretch film PE enclosure film Crystallinity change: For partially crystalline stretch film materials, temperature increase may cause the crystal structure of the crystalline region to melt to a certain extent. The originally regularly arranged crystalline part becomes disordered, which makes the structure of the entire material softer and more plastic. The increase in non-crystalline areas also provides more space for the movement of molecular chains, which is conducive to achieving greater deformation during stretching, thereby increasing the stretch ratio.

Large roll stretch film PE enclosure film Reduced elastic modulus: Increased temperature will cause the elastic modulus of the stretch film to decrease. The elastic modulus is an indicator of the material's ability to resist elastic deformation. A reduced elastic modulus means that the material is more likely to deform when stretched by external force. Under the same tensile force, the lower elastic modulus allows the wrap film to produce greater strain, that is, the stretch ratio increases.

Temperature reduction

Large roll stretch film Packaging and transportation stretch film PE enclosure film Limited molecular chain movement: When the temperature decreases, the thermal motion energy of the molecules decreases, the movement of the molecular chains becomes difficult, the interaction force between the molecular chains increases, and the activity of the chain segments decreases. During the stretching process, it is difficult for the molecular chains to slide and orient freely as at higher temperatures, so the ability of the wrap film to resist stretching is enhanced, it is difficult to be stretched to a greater extent, and the stretch ratio decreases.

Packaging and transportation stretch film PE enclosure film Increased crystallinity: At low temperatures, the crystallinity of some wrap film materials may increase. More molecular chains will be arranged into a regular crystal structure, and the increase in crystal areas makes the material as a whole harder and more brittle. This highly crystalline structure limits the movement of the molecular chains, which can easily cause the material to break prematurely during stretching, and it is impossible to achieve a higher stretch ratio.

Packaging and transportation stretch film PE enclosure film Increased elastic modulus: As the temperature decreases, the elastic modulus of the wrap film increases. The material becomes "harder" and its ability to resist deformation increases. During the stretching process, a larger external force is required to make the wrap film produce the same amount of deformation. In actual operation, it is difficult to stretch the stretch film to a higher ratio at low temperature due to the limitations of the stretching equipment capacity and the strength of the material itself.