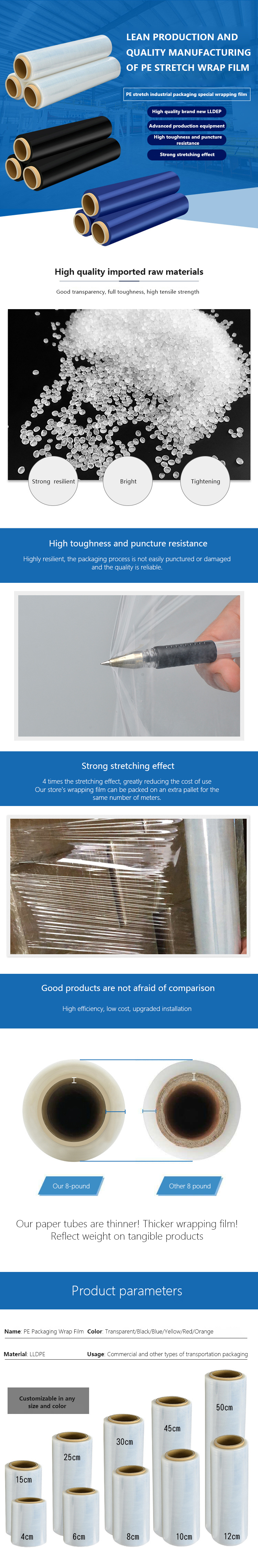

Industrial cling film Strong toughness, good elasticity, not easy to break when used

Large roll industrial film The winding force and retraction are good, ensuring the steadiness of the product

Plastic packaging film The compact type prevents product movement and mutual misalignment during transportation.

Payment terms:We accept T/T,LC,DP and OA30,etc.

Industrial cling film The materials of wrapping film are diverse, and the performance characteristics of different materials are different, which determines their application in different scenarios:

Common materials

Polyethylene (PE)

Industrial cling film Low-density polyethylene (LDPE): has good transparency, softness and tensile properties, excellent low-temperature resistance, good chemical stability, and can adapt to various environmental conditions.

Industrial cling film Linear low-density polyethylene (LLDPE): has better tensile strength, tear strength and puncture resistance than LDPE, can maintain good stability during stretching, and is not easy to break.

Metallocene polyethylene (mPE): has a narrower molecular weight distribution and better physical properties, such as higher tensile strength, tear resistance and optical properties, which can make the wrapping film still maintain good clarity and toughness after stretching.

Large roll industrial film Polyvinyl chloride (PVC): has high transparency and gloss, high mechanical strength, wear resistance, acid and alkali corrosion resistance. It has good self-adhesion and can achieve good wrapping effect without adding additional adhesives.

Large roll industrial film Polypropylene (PP): high transparency, good rigidity, good heat resistance, can be used at higher temperatures without deformation. The surface hardness is high, not easy to be scratched, and can effectively protect the packaged items.

Application scenarios

Industrial packaging

Large roll industrial film Pallet packaging:Plastic packaging film In logistics transportation, PE stretch film is often used to wrap the goods on the pallet as a whole, fix the goods on the pallet, prevent the goods from moving and collapsing during transportation and handling, and protect the goods and facilitate transportation.

Pipe and profile packaging:Plastic packaging film For long strips of items such as pipes and profiles, LLDPE or mPE stretch film can be used for wrapping to protect their surfaces from scratches and corrosion, while also playing a role in moisture and dust prevention.

Plastic packaging film Electronic product packaging: Electronic products usually have high requirements for the protective performance and anti-static performance of packaging. PE stretch film can be used for the packaging of electronic products by adding special treatments such as antistatic agents to prevent static electricity from damaging electronic products, while protecting products from collisions and scratches during transportation and storage.